The Changfeng Street viaduct construction project in Taiyuan has been underway for nearly a month, with over 3,000 workers actively engaged in the development. According to recent updates from the project headquarters, the pile foundation work along the street is now fully underway, and the entire project is expected to be completed by the end of August, after which it will open to traffic.

Changfeng Street is known for its heavy traffic, making it a challenging location for such a large-scale infrastructure project. To minimize disruption, the construction team has implemented a partial closure strategy, which significantly increases the complexity of the work. The project head explained that the working area is only 26 meters wide, leaving very limited space for operations. A 23.5-meter-wide viaduct is being built within this narrow corridor, with some sections occupied by temporary structures. Only one piece of machinery can operate on each side of the site at a time, adding to the logistical challenges.

Additionally, the project involves pouring 327 cement piles along the route, all while carefully avoiding the complex underground utilities. This level of precision makes the construction process extremely demanding, emphasizing the importance of effective site management.

One notable detail observed on the construction site is the color-coded hard hats worn by workers. Red helmets are worn by project managers, yellow ones by construction workers, and blue ones by supervisors. This system not only enhances safety but also improves coordination among different teams, making the workflow more efficient.

Currently, the pile foundation work is in full swing. The project team uses a continuous concrete pouring method, as any interruption could compromise the structural integrity of the viaduct. To reduce noise disturbance to nearby residents, the pouring is scheduled primarily during daylight hours. However, due to the nature of the process, these operations may last for more than a dozen hours, causing some noise. The team hopes for the understanding and support of the local community.

This article is a republished version from an online media source. It reflects the views of the original author and is not necessarily endorsed by this website. If you have any concerns regarding the content or if you believe your rights have been violated, please contact us, and we will address the issue promptly.

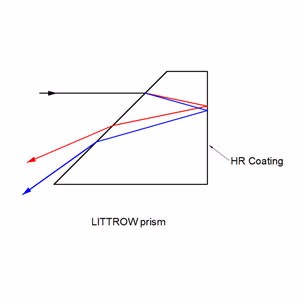

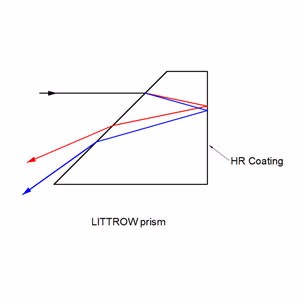

Dispersion Prism

Littrow prisms feature 30°, 60°, and 90° angles .30° - 60° - 90° Littrow Dispersion Prisms can be used for a variety of applications. Uncoated littrow dipersion prisms are used to disperse light into its component spectrum. Coated littrow dipersion prisms are used to deviate the line of sight by 60°.

Dispersion Prisms (Uncoated)

Collimated white light enters into the A-C surface of the prism, is reflected at the hypotenuse surface, and then dispersed into its component spectrum at the B-C surface. Although Littrow prisms produce narrower dispersion than equilateral prisms, Littrow prisms are typically less expensive.

Beam Deviation Prisms (Coated)

Incident light enters into the aluminum coated B-C surface of the prism at the nominal angle and returns back using the same path. In spectrum dispersion applications utilizing white light, the resolution performance of Littrow prisms is equal to equilateral prisms since the optical path length through the glass substrate is the same distance round-trip. Additionally, light entered into the A-C surface will reflect twice inside the glass substrate before being emitted through the hypotenuse surface at 60°.

Â

Dispersion Prism,Optical Dispersion Prisms,Beam Deviation Prisms,Inked Dispersion Prism

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com